Quality Certification

ISO 9001 & ISO 13485 Certification

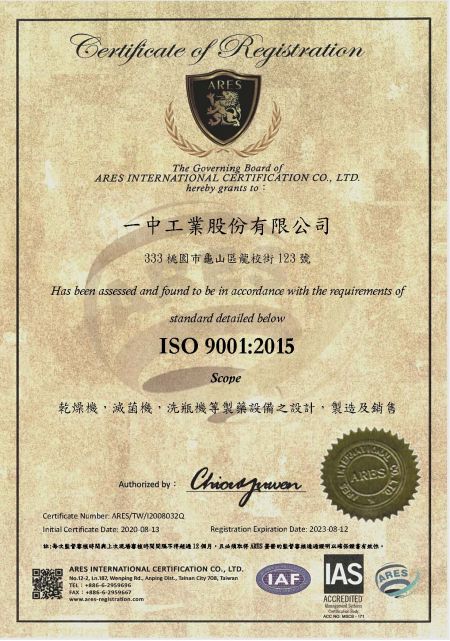

ECMC (E Chung Machinery Company) has been assessed and found to be in accordance with the requirements of standard ISO 9001:2015 Quality Management System Certification.

• International Verification Organization: ARES International Certification Co., Ltd.

• Scope: Design, Manufacture and Sale of Dryer, Sterilizers, Washing Machine and other Pharmaceutical Equipment.

• Certificate Number: ARES/TW/I2008032Q

• Date of Initial Issuance: 2020-08-13

• Date of Expiration: 2023-08-12

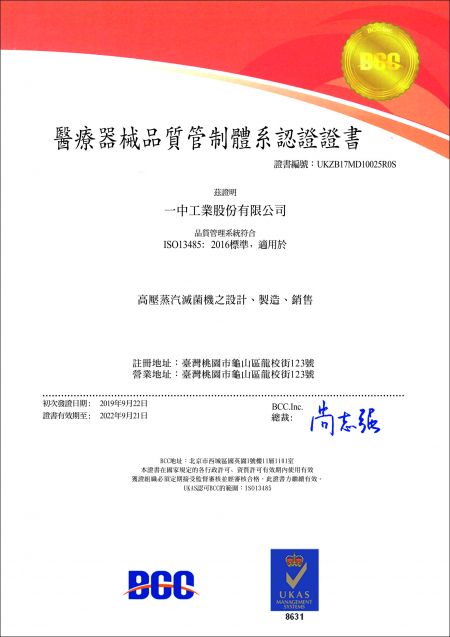

ECMC (E-Chung Machinery Company) has been assessed and found to be in accordance with the requirements of standard ISO 13485:2016 Medical Device Quality Management System Certification.

• International Verification Organization: BCC Inc.

• Scope: Design, Manufacture and Sale of Autocalve (Steam Sterilizer).

• Certificate Number: UKZB18MD20033R0S

• Date of Initial Issuance: 2019-09-22

• Date of Expiration: 2022-09-21

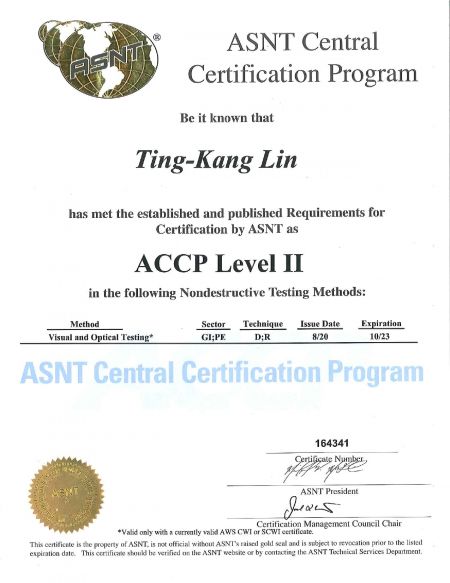

- ACCPLevelI_Visual & Optical Testing

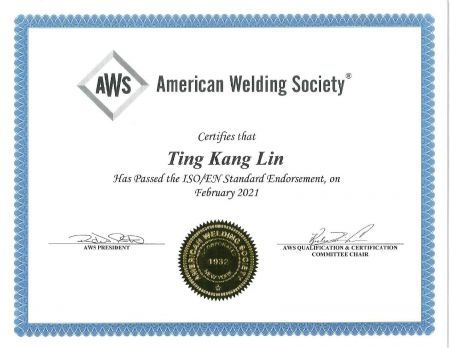

- Welding

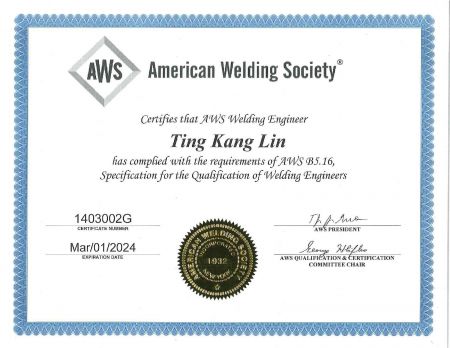

- Welding Engineer

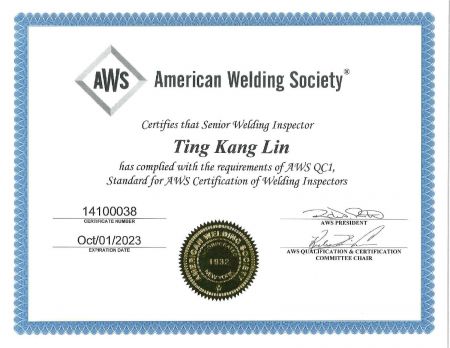

- Welding Inspectors

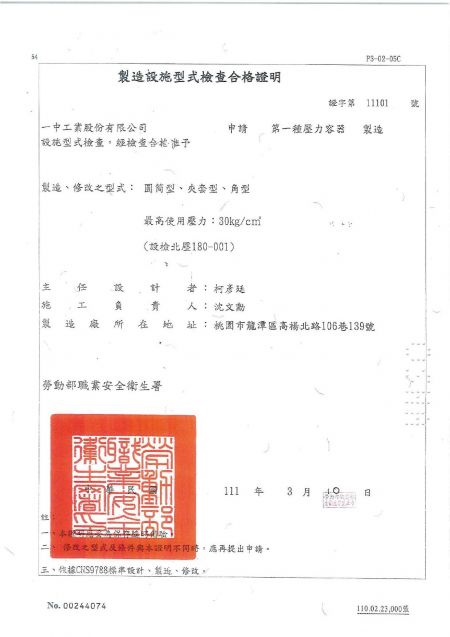

- Cylinder_Jacket_Square_Rectangle

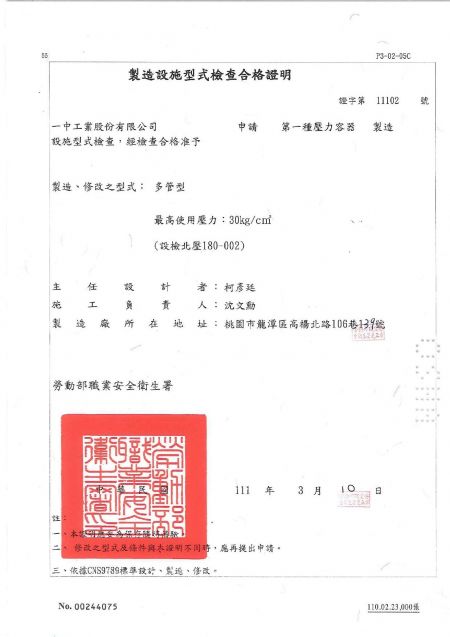

- Multiple Casts

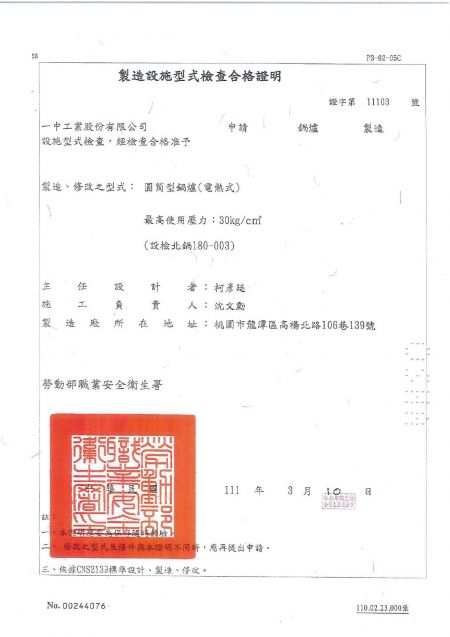

- Cylindrical Boiler_electric heating

- ISO9001 Certification

- ISO13485 Certification

- IMS Certification

▲ What is the ISO 9001 quality management system certification? ▲

ISO 9001 Quality Management System (ISO 9001 Quality Management System) certification is a set of standards established by the International Organization for Standardization (ISO) to check whether the products or services provided by the company can maintain a certain quality Quality management certification system. ISO has strict certification conditions and is a strategic partner of the WTO's global trading system. It is not difficult to see its credibility. In addition, the International Organization for Standardization also claimed on its official website that about 1 million companies in 170 countries have passed the ISO 9001 quality management system certification.

Currently commonly used ISO 9001:2015, where "ISO" stands for the abbreviation of the International Organization for Standardization; "9001" refers to the international standard number of this indicator; "2015" refers to the ISO 9001 standard released in 2015 The updated content is like the concept of version numbering.

The quality management principles are: customer orientation, leadership control, full participation, process methods, organizational situation, continuous improvement, factual decision-making, etc. to establish a set of operating procedures and make systematic planning to assist companies in quality management through ISO 9001 If the above principles can be effectively applied, it can lead the company to make its operating quality meet the needs of customers.

▲ Why is ISO 9001 certification required? ▲

The ISO 9001 quality management standard system provides a clear standard procedure that can assist in the development and performance of the organization, and demonstrate first-class service quality. As many countries currently certify ISO 9001 and use it as a unified standard for verification, this verification system is necessary if you want to enter the international market. Furthermore, the ISO standard is authoritative. Obtaining ISO 9001 verification can not only save many companies Audits can also meet government requirements and regulations.

If the company implements the ISO 9001 Quality Management System certification and successfully obtains the ISO 9001 audit verification, the advantages that can be brought to the company include:

• Customer orientation

• Leadership

• Full participation

• Process method

• Organizational situation

• Continuous improvement

• Factual decision

• Risk thinking

▲ Contents of ISO 9001:2015 revision ▲

Since 2000, the ISO 9001 certification has undergone a major revision for the first time in 2015. The new version of ISO 9001:2015 still prioritizes customers and regards sustainable quality management as the standard, but deletes the principle of "system management method" . The new version of the standard introduces risk management thinking, performance improvement, and adds organizational background and leadership capabilities.

The revised ISO 9001:2015 Quality Management System (Quality Management System) uses the framework of the Annex SL high-level management architecture, so it uses a common architecture with other management system standards to facilitate implementation, integration and verification.

Comparing with the framework of ISO 9001:2008, it can be found that the newly introduced contents include: organizational background, leadership, quality management system planning (response to risks), support (corporate knowledge, ability, communication, etc.), operations (operation planning, product And service customer needs), the final performance evaluation and improvement.

▲ Is ISO 9001 applicable to industries? ▲

Applicable to manufacturers, trading companies, government agencies and academic units in various industries.

▲ What are the benefits of ISO 9001:2015 certification? ▲

ISO 9001 certification can help organizations develop and improve performance, and demonstrate first-class service quality when bidding for contracts.

The organization successfully passed the ISO 9001 standard verification, after which it will be able to:

• ISO 9001 training course

• ISO 9001 difference assessment-can assess the degree of completeness of verification

• Integrated management system verification-audit solutions designed according to the quality and performance standards required by customers

• Process improvement solutions

▲ What is the ISO 13485 medical equipment quality management system certification? ▲

ISO 13485 is a widely adopted standard for medical device quality management systems that comply with regulatory purposes. ISO 13485 ensures that manufacturers can meet the specifications in the process of development, production, manufacturing of medical equipment and other related services. In addition to ensuring quality, it can also improve their operational efficiency.

ISO 13485, published in 2016, was written with ISO 9001:2008 as the main body. Some provisions were added or deleted in response to the characteristics of the medical device industry. The core of the new version of ISO 13485:2016 was revised to emphasize risk management, verification, and strengthening of supplier control. Therefore, it is more suitable for the complete production chain. It is also matched with the implementation of the MDSAP medical device single audit program and the concept of GMP regulations, and it has reached a unified standard with the European Union Medical Device Directive. Although ISO 13485 is written on the basis of ISO 9001, companies that only comply with the ISO 13485 standard cannot claim that they also comply with the ISO 9001 standard.

▲ Why do we need ISO 13485? ▲

ISO 13485 has clear specifications that can improve efficiency and reduce costs, and also ensure that medical products or related services are safe and effective. In addition, institutions in Europe, the United States, and Canada generally adopt ISO 9001, EN 46001 or ISO 13485 as quality assurance requirements. Therefore, if medical products want to enter the international market, they should comply with the regulations of the relevant authorities.

In order to strengthen the pre-market and post-market management of medical devices and in vitro diagnostic devices, the EU certification agency officially announced the Medical Device Regulation (MDR) to replace the Medical Device Directive (93/42/EEC) on May 2, 2017. The Regulation (IVDR) replaces the In Vitro Diagnostic Device Directive (98/79/EC). The regulatory transition period is set to 3 years. Manufacturers selling products to the EU should update their technical documents and procedures during the transition period to meet the requirements of the new version of the law.

▲ Benefits of ISO 13485 certification ▲

• Comply with regulatory requirements and customer expectations, enhance product value and company image

• Review and improve the processes within the enterprise organization to improve production efficiency and reduce the risk of products after the launch

• Prove that it can provide safe products and strengthen the ability and opportunity to enter the international medical industry supply chain

• Break through the barriers of international trade and expand the global medical equipment market

▲ ISO 13485 applicable objects ▲

Medical device manufacturers, innovative R&D companies, final product manufacturers, key component suppliers, special process providers, sterilization service providers, after-sales service providers, warehousing and logistics service providers, distributors/sellers, medical device semi-finished products manufacturers You can also apply for ISO 13485, but you must prove its intended use.

▲ Major changes in ISO 13485:2016 ▲

In this 2016 revision, ISO 13485 is more applicable to the entire supply chain of medical equipment, establishing stricter safety assessments, strengthening concepts such as risk management, validation verification, and supplier control, and simultaneously incorporating computer application software into the norms. Improve the quality of overall medical equipment.

Other major changes include:

• Introduce the concept of product lifecycle management

• Emphasizes risk management and serves as a basis for consideration

• Set clear specifications for the software validation used in the quality control system

• Strengthen supply chain management and control

• Pay more attention to the feedback mechanism

• Strengthen Management Responsibility (Management Responsibility)

• Specify corrective / preventive actions (Corrective Action Preventative Action, CAPA)

• Clearly define Process validation and Post market activities

• Establish a medical device file and document the process (Document)

• New pollution control (Contamination control)