Steam-Air Mixture Sterilizer (Autoclave)

APST

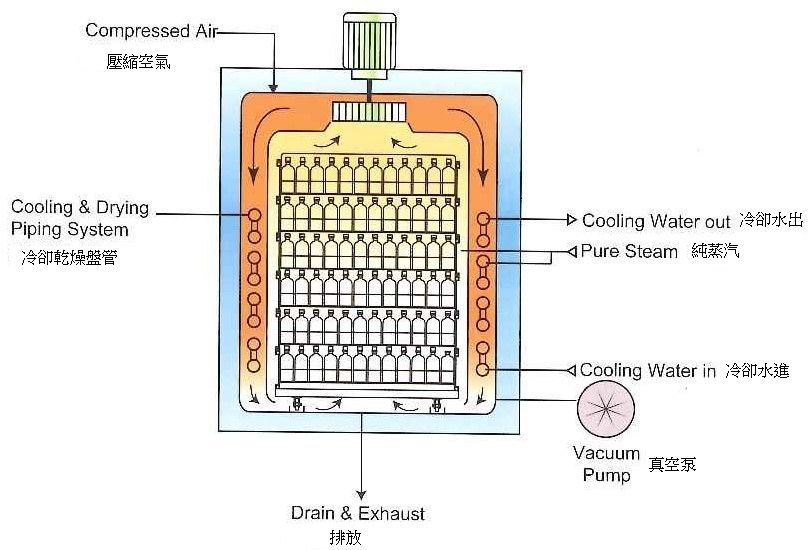

Sterilization on Autoclave Steam-Air Mixture Methods is designed to sterilize liquids in closed or opened containers with a mixture of steam and air. After the product is cooled, it will be dried with steam-air at the end of the sterilization process. Sterilization temperature is adjustable from 104℃ to 134℃ with a tolerance of ± 0.5℃.

ECMC Control System

ECMC (E CHUNG) sterilizer control system is in compliance with current GAMP standards.

Software programs researched and developed by ourselves ECMC, that are all validated.

PLC adopts Mitsubishi and Siemens.

HMI adopts Siemens and Pro-Face.

Chamber leaking test program.

The panel uses HMI Touchscreens control.

Program flow: Use HMI control, provide sterilization programs or by customized specifications.

Simple & safe operation: The automatic programs provide with complete and safe control accordingly.

Temperature records are in continuous monitoring and recording during the sterilization process.

Optional: RS232, USB or CF card by which can be connected with the computer directing to calculate F0 value.

Comply with European Regulatory Standards EN 285, EN 554, and HTM 2010.

The operating password set in stages.

Being with Graphical Control Interface.

Being in accordance with FDA 21 CFR PART 11.

Features

- The sterilizer designed for sterilization with a mixture of steam and air in closed or opened containers.

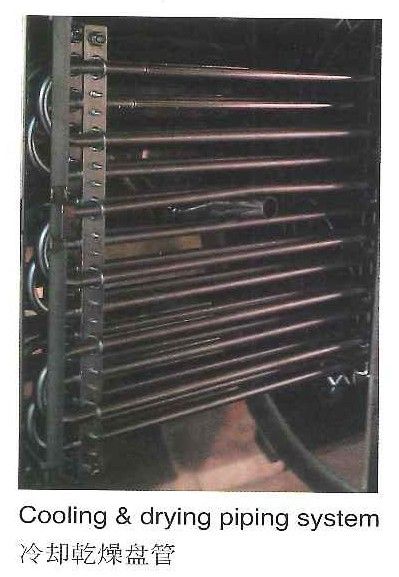

- As the product disinfected, the cooling and drying are at the same process afterwards.

- A tolerance of temperature is at ± 0.5℃ while the adjustable sterilized distribution set from 104℃ to 134℃.

Applications

- LVP/SVP Sterilizer

- Plastic bottles & Membrane bags

- Ampoules sterilizer & Leaking test

- Glass bottles

- Vial bottles

Specification

- The panel is controlled by LCD touchscreens.

- Program flow: It adopts HMI control, simple operation, and provides three kinds of disinfection programs or specifications that required by customers.

- Simple and safe operation: The automatic program provides complete and safe control to ensure a safe operating state.

- Continuously monitoring and recording by the temperature recorder during sterilization process.

- The machine structure is all made by stainless steel SS304, 316, 316L, which completely meets the requirements of cGMP.

- The door of the equipment is sealed with silicone. There is no concern about steam leakage due to the doors can be closed tightly.

- In the multiple sterilization process, vacuum, temperature, pressure and time can be set freely and be specified various process according to customers' requirements.

- The automatic temperature controller adopts P.I.D. automatic calculation, and displays the actual temperature value by LED at the same time.

- The door is equipped with an interlocking device to avoid pollution that caused by different levels of air.

- The six-point multi-function recorder device can completely record the temperature distribution and pressure status at each point during sterilization. (Optional: 12-point temperature recorder can be purchased according to the equipment's size).

- Steam Heating inside the jacket, and keeping temperature steady for vacuum drying.

- The vacuum breaker is equipped with a 0.2 µ M absolute filter device, which can prevent the sterilized products from being contaminated, and directly sterilize through the steam pipeline at the same time.

- Single-door or Double-door through-type designs are both available.

- Equipped with a temperature confirmation hole, which enables QA to measure the F0 value of no-load heat distribution and full-load heat penetration in the autoclave. It can also be connected with computer for monitoring (RS232).

Specification

| Standard Model (APSR,ASWR,APST,EOG) | Capacity(Liter) | Steam Consumption (Kg/Hr) | Chamber Dimension (m/m) | External Dimensio (m/m) | ||||

|---|---|---|---|---|---|---|---|---|

| W | H | D | W | H | D | |||

| 200 | 200 | 55 | 500 | 500 | 800 | 1200 | 2000 | 1100 |

| 360 | 360 | 60 | 600 | 600 | 1000 | 1350 | 2100 | 1300 |

| 480 | 480 | 100 | 600 | 800 | 1000 | 2000 | 2150 | 1300 |

| 600 | 600 | 120 | 600 | 1000 | 1000 | 2000 | 2150 | 1300 |

| 1000 | 1000 | 150 | 800 | 1000 | 1250 | 2800 | 2300 | 1550 |

| 1200 | 1200 | 150 | 1000 | 1000 | 1200 | 3100 | 2300 | 1500 |

| 1500 | 1500 | 160 | 1000 | 1000 | 1500 | 3100 | 2300 | 1500 |

| 1800 | 1800 | 160 | 1000 | 1200 | 1500 | 3100 | 2500 | 1800 |

| 2160 | 2160 | 200 | 1200 | 1200 | 1500 | 3300 | 2500 | 1800 |

| 5400 | 5400 | 250 | 1200 | 1500 | 3000 | 3300 | 2800 | 3300 |

※ We can accept customer specify specification.

Control System

- ECMC (E Chung) sterilizer control system are in compliance with current GAMP standards.

- Software programs by ECMC (E Chung) company's own research and development, and through validation.

- PLC can be used Mitsubishi, Omron, Siemens, etc.

- HMI: Human Machine Interface Pro-Face.

- Chamber leaking test program.

- The panel uses LCD touch screen control.

- Program flow: Use HMI control, provide sterilization programs or by customer specifications.

- Simple & Safe operation: The automatic programs provide with complete and safety control to ensure safe operating condition.

- Temperature recorder for continuous monitoring and recording of the sterilization process.

- Option RS232 or USB, CF CARD can connect with computer direct to calculate F0 value.

- Comply with European Regulatory Standards EN 285, EN 554, and HTM 2010.

- Operator password to set.

- Graphical control interface.

- In accordance with FDA 21 CFR PART 11.

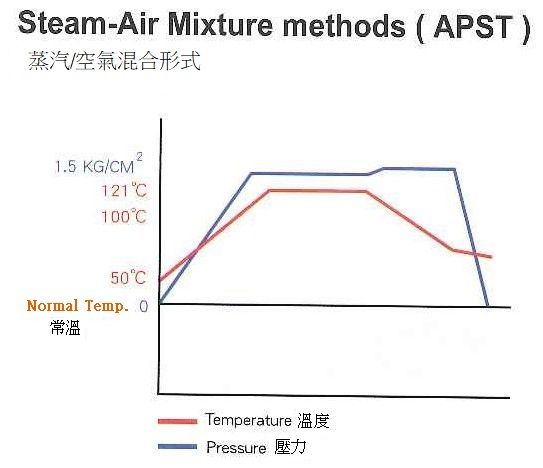

Process

Steam-air Mixture methods

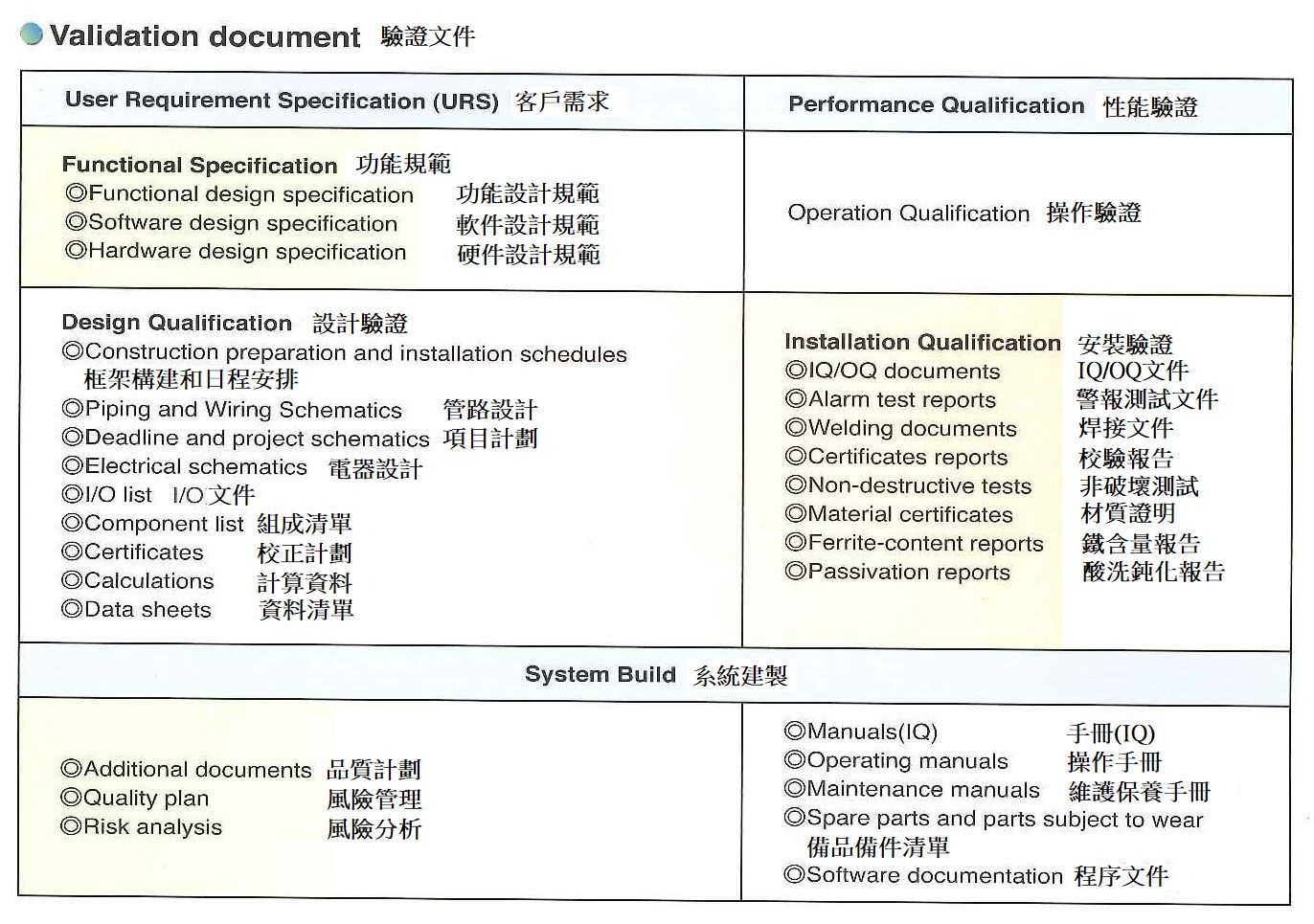

Validation document

- Gallery

- Related Products

Steam Sterilizer (Autoclave)

APSR-01

The Autoclave Steam Sterilizer has a touch panel with Human Machine Interface (HMI), signal...

DetailsSuperheated Water Sterilizer (Autoclave)

APWR-01

Autoclave Superheated Water Sterilizer is a highly efficient sterilization process for airtight...

DetailsE.O.GAS Sterilizer

E.O.GAS Sterilization can be used to sterilize objects that are not suitable for high temperature...

Details

Steam-Air Mixture Sterilizer (Autoclave) - Autoclave Steam-Air Mixture Sterilizer | Taiwan-Based Pharmaceutical & Biotech Manufacturing Equipment Manufacturer | E CHUNG MACHINERY CO.

Located in Taiwan since 1975, ECMC (E CHUNG MACHINERY CO.) has been a pharmaceutical and biotech processing equipment manufacturer. Main products, including Steam-Air Mixture Sterilizer (Autoclave), autoclaves, WFI, water systems, pure steam generators, superheat water sterilizers, vial washing machines, tunnel sterilizers, and, in particular, hot air and steam sterilizers.

ECMC (E CHUNG) company is a professionl experienced manufacturer in the pharmaceutical sterilization industry more than 48 years so that our customers located worldwide. Sterilization machines are manufactured in line with current international standards (EU standards, US standards, GMP and GAMP, etc.).

ECMC (E CHUNG) has been providing customers high-quality cGMP pharmaceutical and biotech processing equipment, both with advanced technology and 48 years of experience, ECMC (E CHUNG) ensures each customer's demands are met.

)